[in cooperation with BLACKBIRDS]

Company introduction

DiBO develops and produces cleaning machines and systems. Extremely solid, high quality products, developed for a long life of intensive use. The characteristic green color of the DiBO cleaning machines enhances the company motto “#CleanGREEN! … for a cleaner and greener world”.

Product introduction

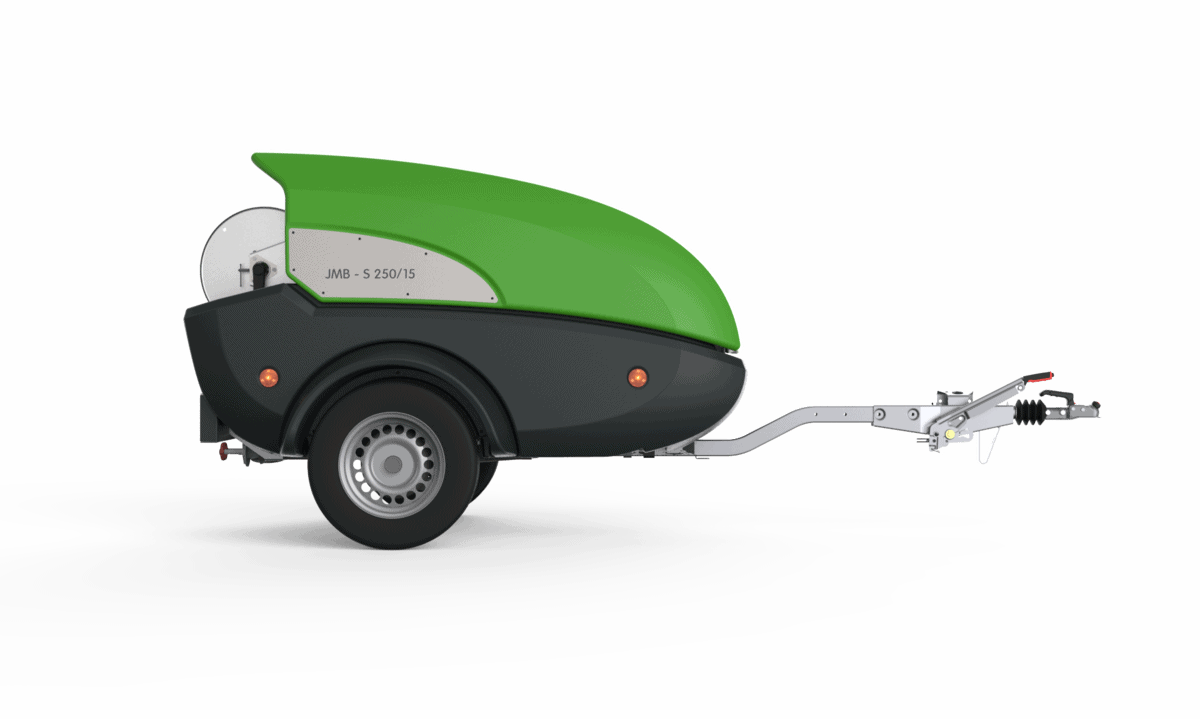

The JMB-S is an ultra-compact mobile hot water high-pressure cleaner and the result of a successful collaboration between DiBO and GBO Innovation makers. The new model is equipped with the most modern and sustainable technology and has a lower consumption than its predecessor.

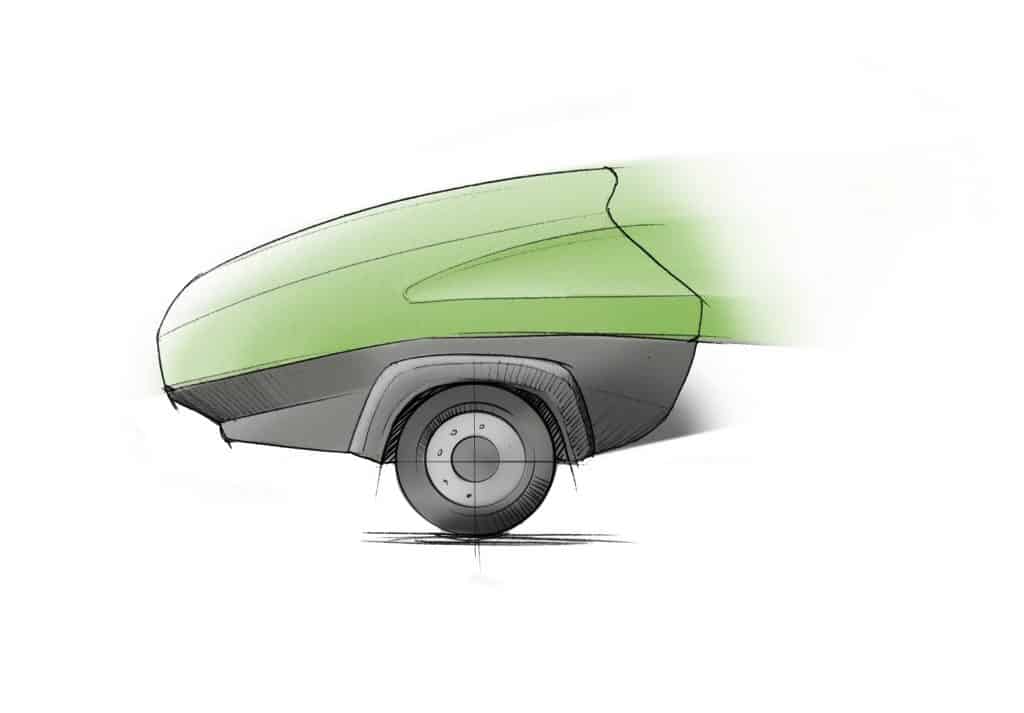

The new styling focuses on a robust performance machine, which is easier to produce, lighter, has greater capacity and autonomy.

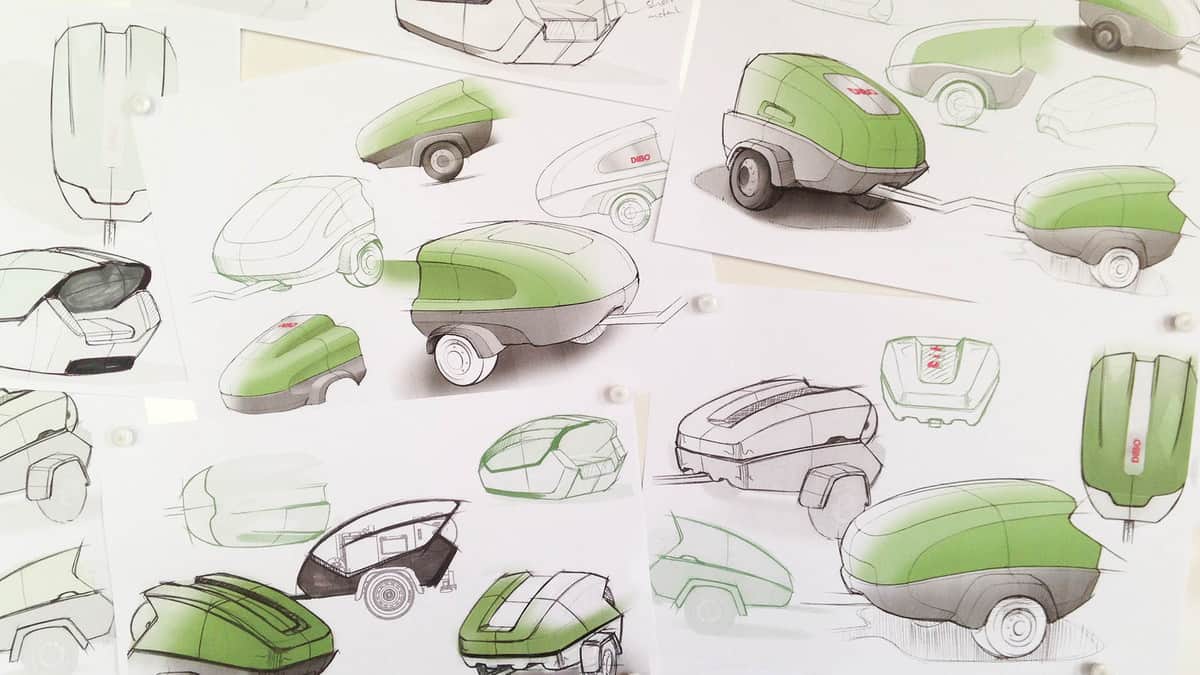

Product design

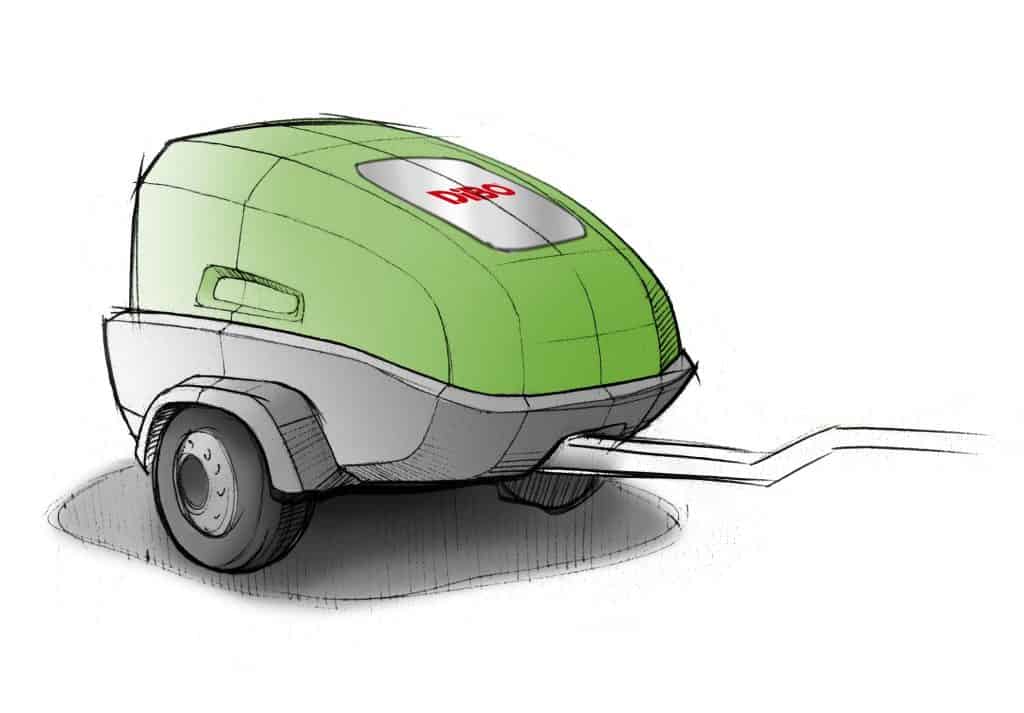

In addition to the strong improvement in usability, user interface and making the machine intelligent, a great deal of attention was paid to developing a design DNA for the new DiBO machines. As a result, DiBO can now also position its strengths with a clear styling.

The new styling focuses on a robust performance machine, which is easier to produce, lighter, has greater capacity and autonomy and can also be lifted for the first time with a construction crane.

Product engineering

Both the water tank and the top valve are produced by rotational molding. Rotational molding makes it possible to create spaces through which the water tank can be installed over the entire circumference of the trailer. The design of the top cover contributes to better sound insulation and gives the machine a robust character.

The trailer is extremely lightweight (750 kg) and has a low center of gravity for optimum weight distribution.

Questions?

Don’t hesitate to ask them. Also, have a look at a similar case in the Agriculture sector.